|

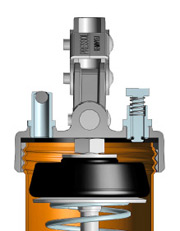

Performance after 40,000 operating cycles virtually unchanged

- Pump piston, cylinder and O-ring with 6 μ fit (no dummy lubrication)

- Operates with greases NLGI grade 3

|

|

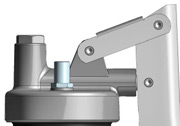

Variable stroke

- At high back pressure, e.g. gummy lubrication point, lubrication can be achieved with significantly less effort by shorter strokes

- Grease supply variable from 0,1 to 1,6 cm³ per stroke

- Optimal leverage for operating the hand lever, thus the compressive force required is as low as possible

|

|

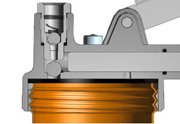

No crushing hazard

|

|

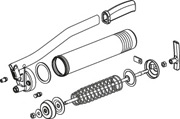

Cleaning – Spare parts

- Easy to clean – Each component group and parts can be supplied as spare parts

|

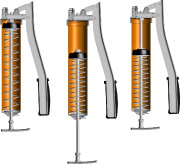

Different grease gun colors for different grease types

|

|

|

Grease pressure relief

- Push rod can be locked in any position – push rod does not have to be fully retracted to release the spring pressure on the grease (grease does not saponify)

- Damaged cartridges can easily be removed

|

|

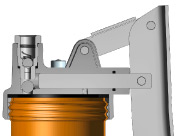

Grease gun head, zinc die casting Z 410

- one-piece

- pressure resistant

- safe

|

|

Filling nipple and ventilating valve

- Filling nipple (FN), M 10 x 1 a (12 670)

- optional vent valve (ETV), M 10 x 1 a (85 277)

|

|

Rolled threads

- Rolled threads on the grease gun tube are insensitive to impact damage and enable quick and easy screwing-in

|

|

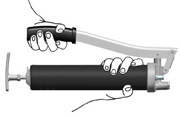

Everything under control

- Ergonomic handle, non-slip, excellent power transfer and handling

- T-grip, optimized grip and pressure optimised

|